Production - Schedule

Velosity calculates the Schedule automatically. The Scheduler takes all required information into account:

- The desired sequence of Production Orders (can be changed)

- The router of each Production Order (task name and duration)

- Working hours (Company and per Task)

- Non-Working Days (holiday)

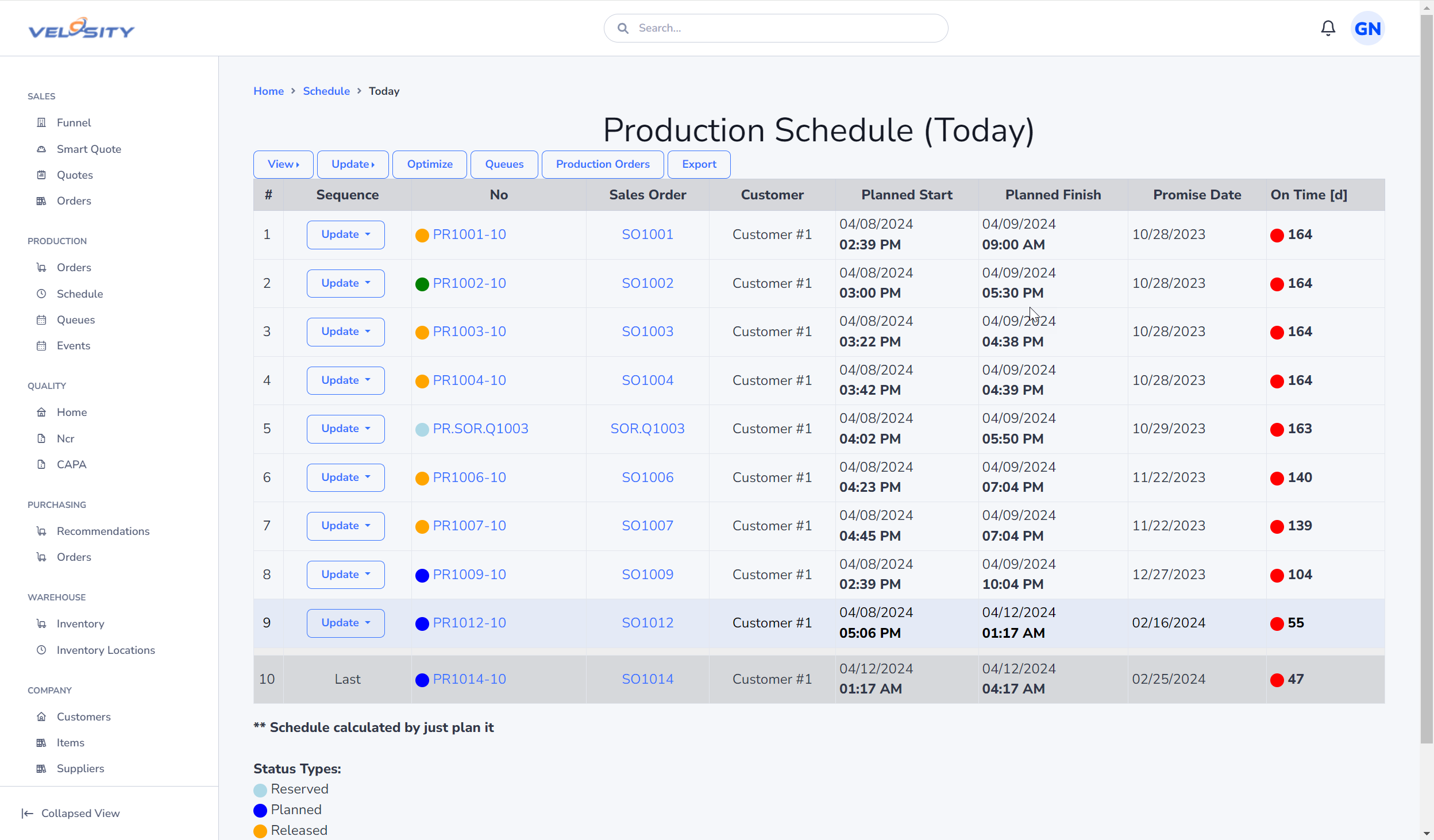

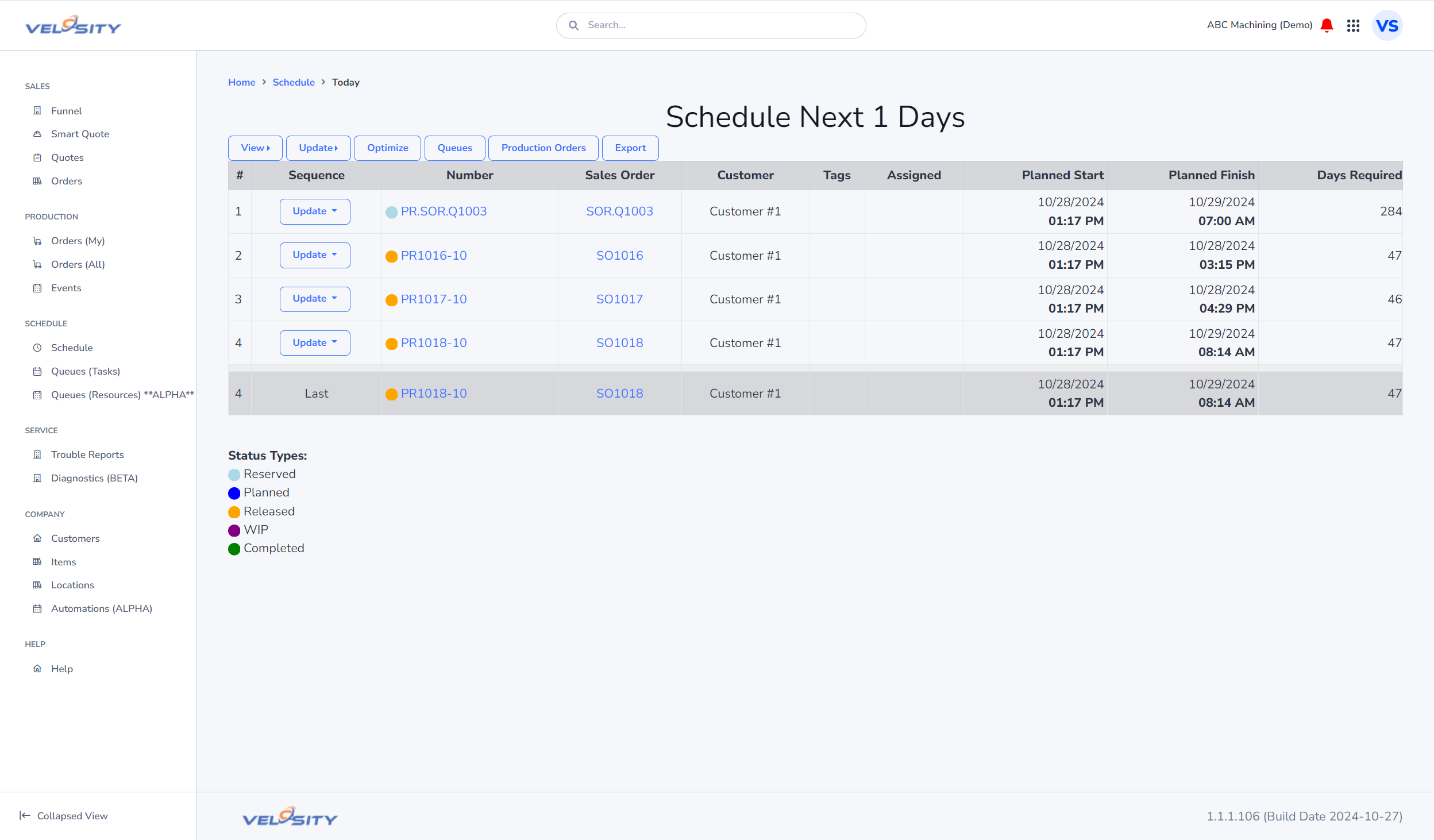

Schedule

This view shows the schedule - viewable in various time intervals (today, next 3, next 7, next 30 days) and in various ways:

- List

- Gannt

- Calendar

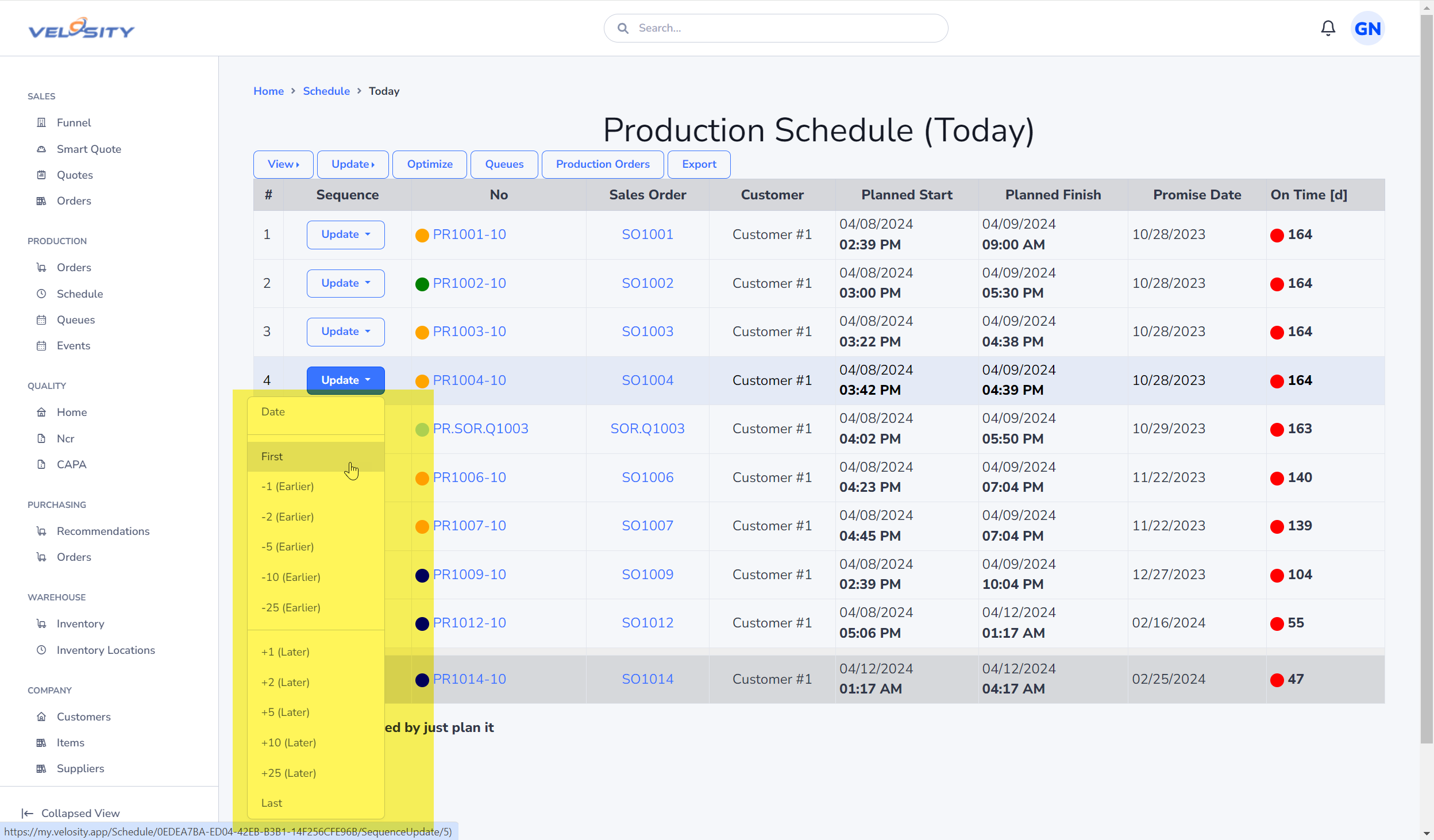

Change Sequence Number

You can change the sequence number of any production order. If the number of production orders is less than 50 the Scheduler will automatically run. Otherwise, click on Schedule, Update to update the schedule.

The production order should appear in the desired position and all other production orders will have updated start and completion dates/times.

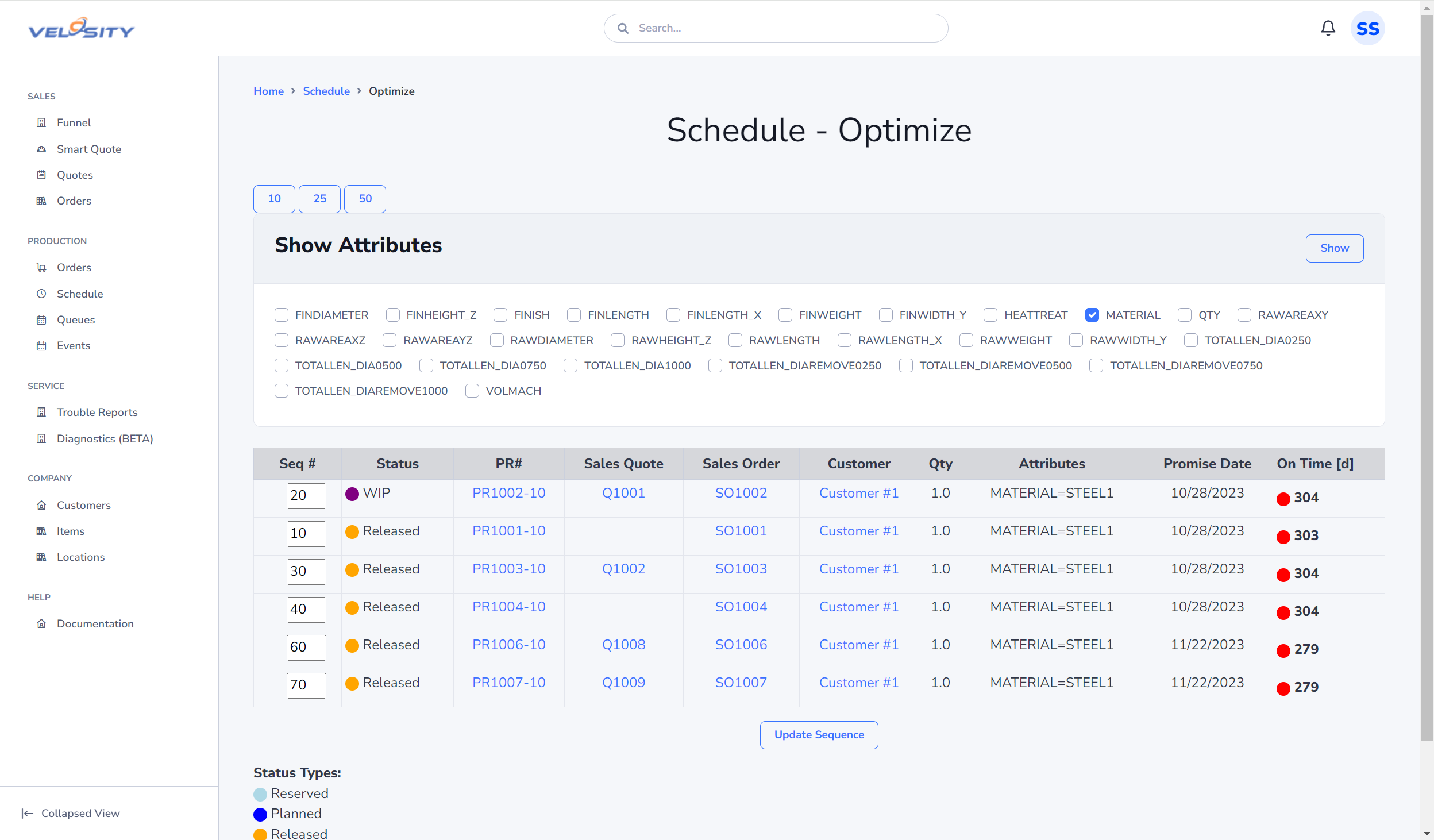

Optimize

This view provides a update sequence number of production orders based on one or more attributes. You might need to change the sequence of orders by batching around a particular material for example.

Once the desired attributes (one or more) are displayed, you can enter the sequence numbers for each. Sequence number can be any increment (1, 2, 5). Update the Schedule when you are done (Schedule/Update) to ensure the changes in sequence are reflected.

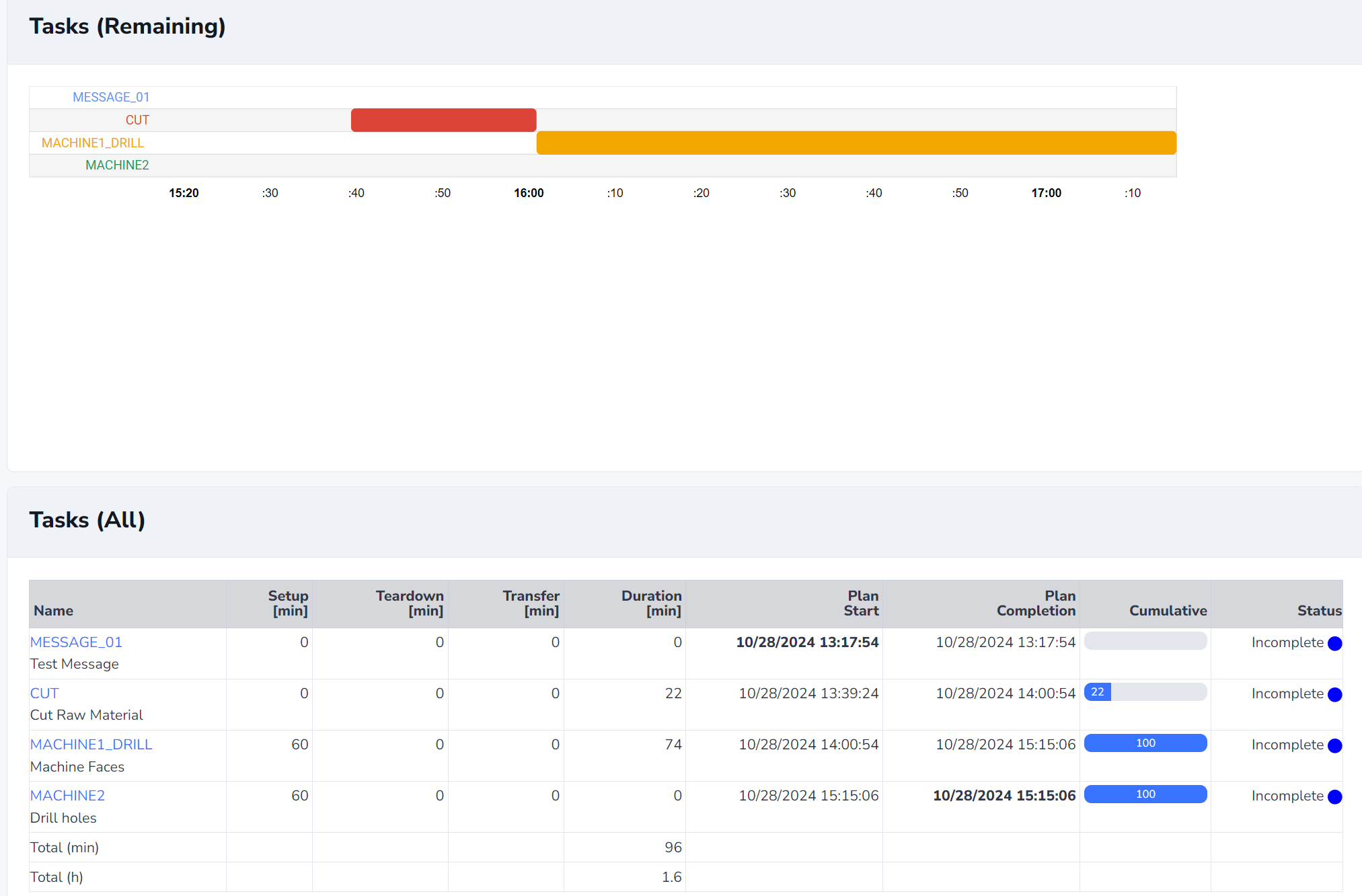

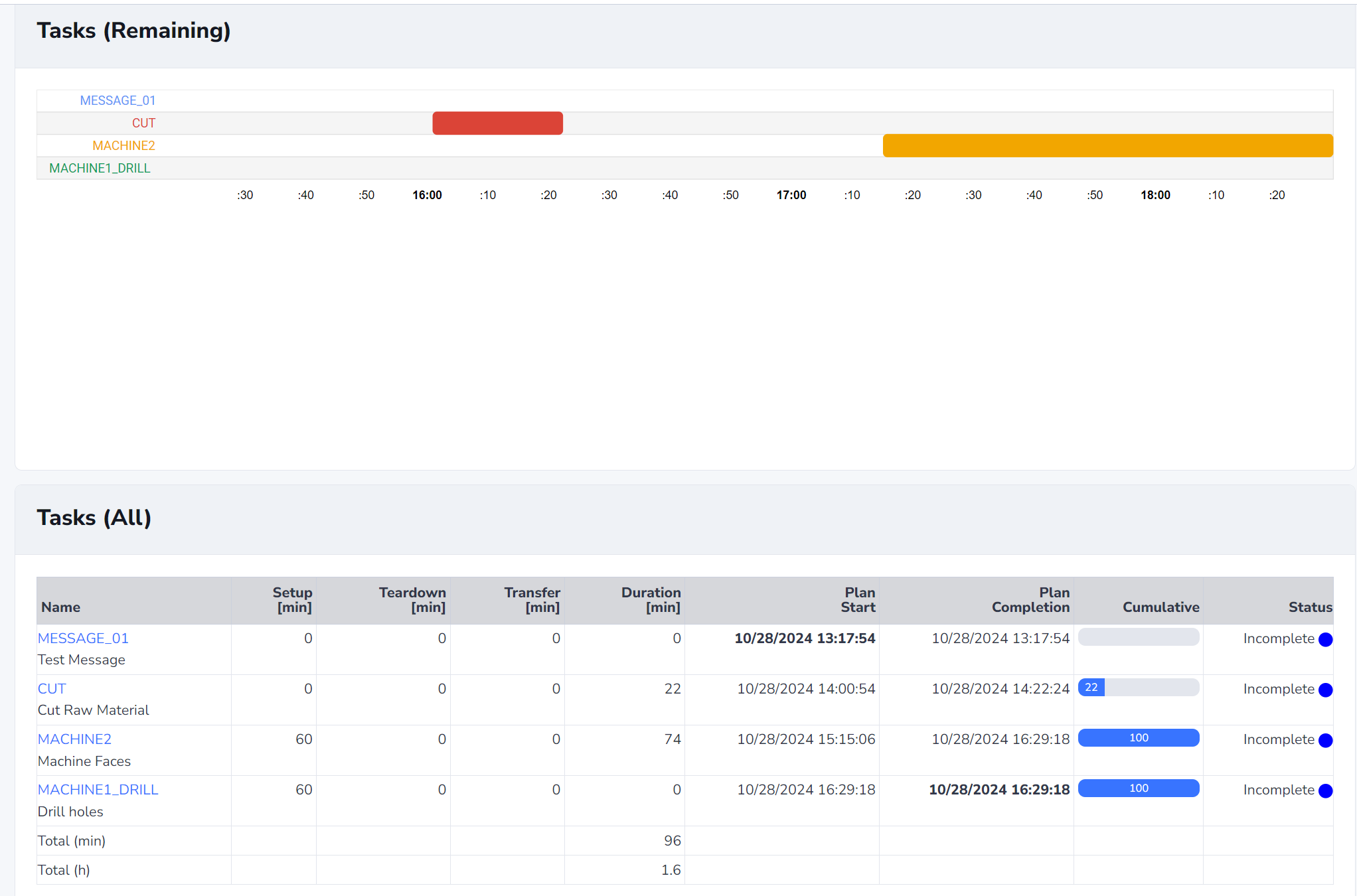

How It Works

The Scheduler walks the list of Production Orders sorted by the Sequence Number (ascending). For the firsrt production order, the tasks in the router are scheduled one after the other. The start time of the second task is the time of completion of the previous, and so on. Start times are adjusted for Task working hours - regular and exceptions (holidays, downtime, etc).

If no Resources are specified with the Task is added to the router, then the Default Resource is used. This means effectively that you have one production person to handle all of the work (not typical of course!). To make Velosity properly model your production environment you should add Resources - one per person. You can specify Resource Groups that each Resource is a member of. For a machine shop there might be these Resource Groups: 1) CNC, 2) LATHE, 3) GRIND. You would mark which groups each Resource should be a member of (qualified for). The Scheduler considers all of the requested Resources for the start time, delaying Task start until the requested resources are available.

Automatic

The Scheduler runs daily at midnight UTC.

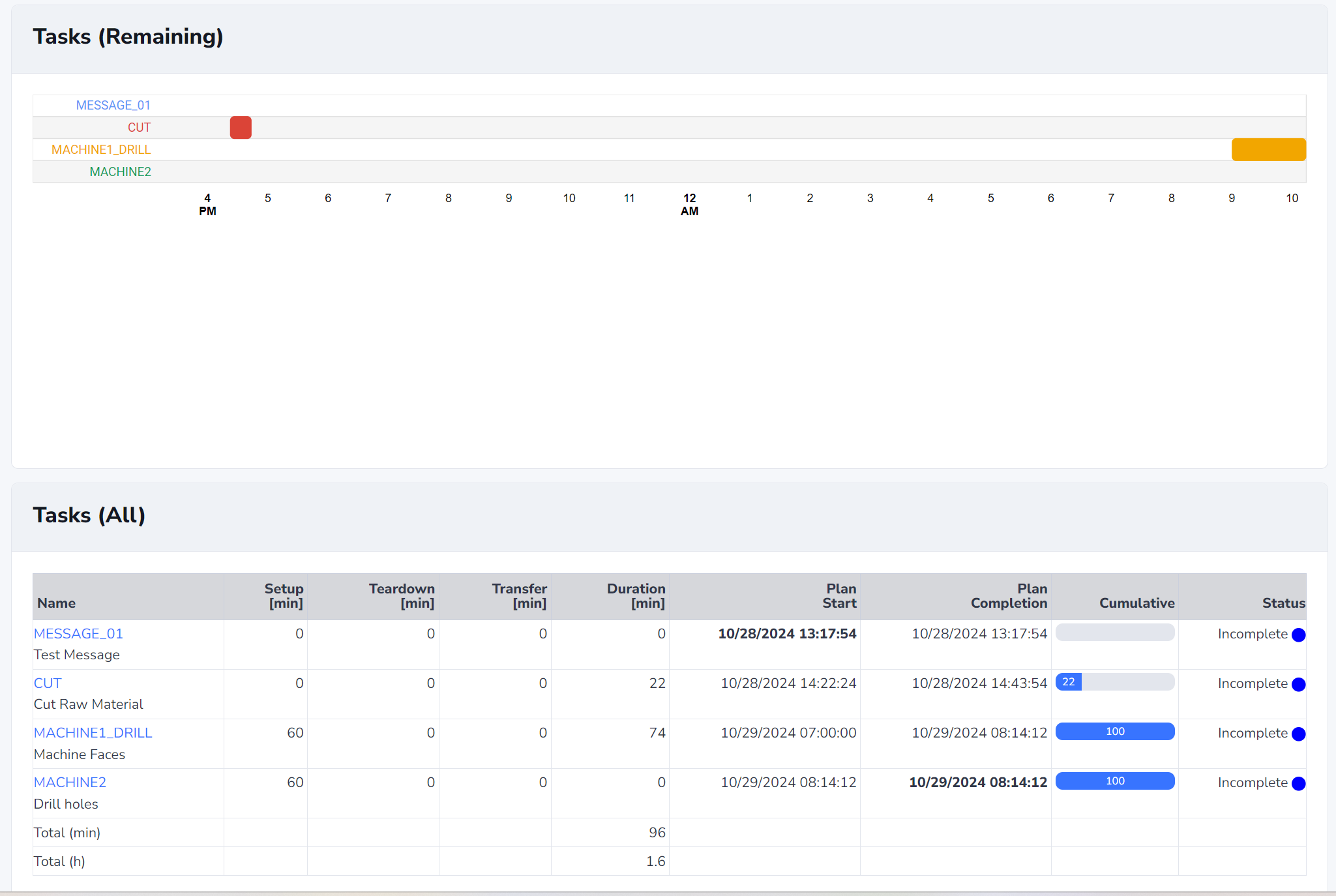

Example

Four production orders are scheduled. If you compare the 3 production orders, you can see that the tasks are stacked as you expect (one resource in this example doing all of the work). Large gaps in the start/finish are from evenings and weekends (non-working hours).

1)

2)

3)